Free Instructions On Assembling Air Cleaner Ducting for V8 Conversions

Why You Might Want To Assemble Ducting. Ducting cooler outside air from in front of the radiator to the air cleaner can increase engine horsepower 5% (more than some headers)! Another benefit from ducting is to substantially reduce intake noise compared to an open element air filter.

You get a quantity discount for ordering more elbows and longer tubing.

EXAMPLE DUCTING APPLICATIONS

TPI-S10 Cold Air Induction

On this TPI S-10, the air cleaner ducting is connected to an air filter from a 1993 S-10 4.3 V6 CPI engine, which gets cool air from in front of the radiator. The ducting shown, from the throttle body to the air cleaner assembly are one 4" x3.5" x90° rubber elbow, two 3"x90° rubber elbows, and two 3"x45° rubber elbows.

On this TPI S-10, the air cleaner ducting is connected to an air filter from a 1993 S-10 4.3 V6 CPI engine, which gets cool air from in front of the radiator. The ducting shown, from the throttle body to the air cleaner assembly are one 4" x3.5" x90° rubber elbow, two 3"x90° rubber elbows, and two 3"x45° rubber elbows.

Originally, this TPI engine used an open element air filter connected directly to the throttle body. The radiator would heat the intake air to about 200° F on warm days.

With the system shown, the owner claims the temperature of air going into the engine was reduced by over 60° F. Typically, power increases 1% for every 11° F temperature drop of the intake air due to the increased density of the cooler air. In this application, the ducting is good for a 5% power increase.

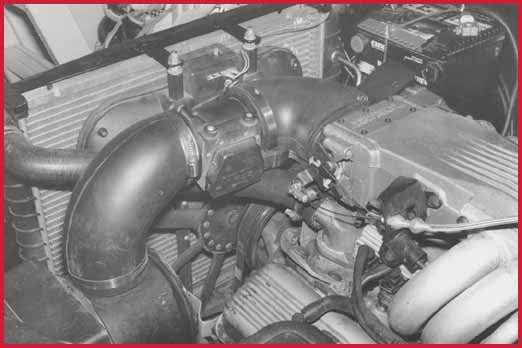

Ducting to Handle the Engine-Drive Fan Needed for Towing

The only way to make a car run cool while towing is to use an engine-driven fan. Electric cooling fans just don't make the grade when towing heavy loads up hills. The ducting shown below accommodates an engine-driven fan and is flexible enough to allow for normal engine movement.

The only way to make a car run cool while towing is to use an engine-driven fan. Electric cooling fans just don't make the grade when towing heavy loads up hills. The ducting shown below accommodates an engine-driven fan and is flexible enough to allow for normal engine movement.

The car shown below is a 1981 Chevrolet Malibu (G-Body). The parts used are:

- 4" x3.5" x90° rubber elbow.

- 3"x90° rubber elbow with 1" long 3" o.d. aluminum tubing inside that has been flattened (ovalized) to improve hood clearance and appearance.

- 33"x90° rubber elbow.

- 3"x45° rubber elbow

- MAF sensor, or 3" o.d. aluminum tubing.

- Duct from 1988–1989 Pontiac Firebird TPI.

- Not visible: "Top loader" air cleaner from 1988–1992 TPI Pontiac Firebird.

- Upper radiator hose is from 1991 Caprice. It is spliced into an upper radiator hose of a 1988–1992 Camaro TBI. The thermostat housing is also from a 1988–1992 Camaro TBI.

Air Cleaners and Ducting 1966 Chevy II

This 1966 Chevy II (Nova) has a 1985 305 TPI engine from a Camaro. The air cleaner ducting is 4x3x90° at the throttle-body and 3x90° to the air cleaner.

The 4x3x90° rubber elbow has a thick wall (7/16") at the 3" end, preventing a good fit of the connector to the MAF sensor. We trimmed the hose so the wall thickness was only 1/4" in the area of the connector. This can be done with a razor blade, or with a belt sander.

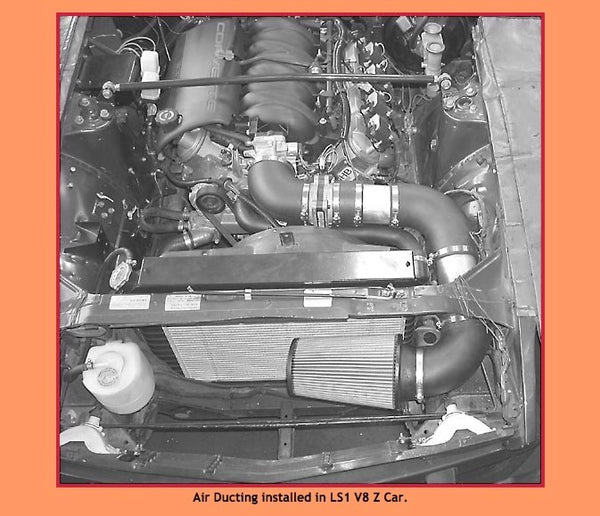

Installed Air Ducting, Datsun Z LS1 V8.

Important Installation Tip. Note that the rubber elbows and tubing were sometimes trimmed, stretched or shaped in the above examples. For example, 1" long pieces of the aluminum tubing can be placed inside the elbow to allow forming the cross-section into a desired shape (i.e. to flatten ducting into an oval shape for clearance reasons). When connecting rubber pieces together, 2" long pieces of aluminum tubing work well as a splice.