Introduction. Chapter 1 from the S10 V-8 Conversion Manual (14th Edition)

S-10 V8 Engine Swaps, V8 Engine for S10

Before we get started with all the variations and nuances, let's start with the simplest version of the story.

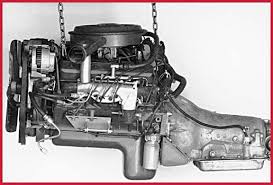

A 1982–1992 Camaro V-8 engine and 700-R4 transmission can be put into an S-10 with just a few changes.

The only changes required on this engine to fit it into a 4x4 are the motor mounts, the oil pan, and the offset oil filter adapter.

* * *

WHOOPS!

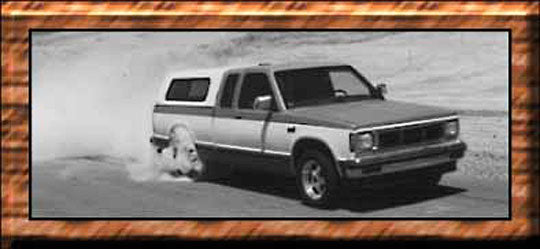

First, a caveat. The above V8 powered S-10 Blazer was real fast. The V8 conversion did not cause the accident, the driver did. Wrecking yards are full of examples of recklessly driven vehicles. Keep that in mind before you even think about showing off the performance of a V8 S-Truck. We have no control over how you drive your vehicle and cannot be held responsible for your actions. The V8 S-Truck can be an extremely high-performance vehicle, and like any vehicle, should not be driven recklessly or somebody will get hurt or killed.

WARNING: The weight gain from the V8 conversion will affect the handling and braking of the vehicle. Also, the payload capacity of the V8 powered S-Truck will be reduced.

* * *

The S-10 Blazer on the left has a 350 V8 Turbo-350 transmission, Toyota transfer case, Toyota front axle, and steering linkage, Ford 9-inch rear-end, 36-inch tires, 2-inch body lift and a 5-inch suspension lift. Many of the non-Chevrolet parts were installed because the stock parts failed. The stock parts did not fail until after the big tires and lift kit were installed. A lot of money had been "invested" (spent) on this truck because of the big tires. After this photo was taken, the truck rolled over and was destroyed. Imagine that—10 inches taller than stock, and it rolled over!

This manual does not get into big tires, lift kits, narrowed rear-ends, wheel tubs, excessive lowering (slammed), big-block engines, blowers, body lifts, monster trucks, or any other modifications that adversely affect drivability, practicality, or safety. This manual shows how to do the V8 conversion using readily available parts from Chevrolet and various aftermarket companies.

A lot of the V8 S-Trucks shown in magazines are not practical. They may look neat, but they live a pampered life, only being driven at (but not necessarily to) car shows. If these trucks were ever driven on the street during everyday driving conditions, they would probably overheat, jar your kidneys, deafen your ears, and run you into the poor house.

The S-Trucks shown in this manual are "daily drivers." They are used for commuting, grocery shopping, trailer towing, vacations, and parts chasing. They are not used for drag racing, street racing, or road racing. They are not taken offroad and jumped. They are just daily drivers.

The S-Trucks shown in this manual are "daily drivers." They are used for commuting, grocery shopping, trailer towing, vacations, and parts chasing. They are not used for drag racing, street racing, or road racing. They are not taken offroad and jumped. They are just daily drivers.

We don¹t want to misrepresent what this manual is about, and we don¹t want to misrepresent what a V8 S-Truck will do.

If this sounds a little "boring", it's because we don't like the "exciting" surprises of an ill-handling, rough riding, unreliable, and expensive vehicle.

The Blazer on the right (with the ultra cool whitewall tires) has a 1988 Camaro throttle-body-injected (TBI) 305 V8 and a Camaro 700-R4 automatic overdrive transmission. It remains stock looking, and is smog legal in California. The Camaro engine is almost exactly as it came out of the Camaro. The air conditioning hoses, power steering hoses, exhaust manifolds, smog equipment, and even the battery cables are from the 1988 Camaro engine. The Camaro 700-R4 automatic transmission also remains stock except for the output shaft, which was switched to the 4X4 output shaft so that the Camaro transmission would bolt to the S-Truck transfer case.

The S-Truck's suspension, transfer case, driveshafts, axles, etc., remain stock. As long as stock size tires are used, the stock parts will be adequate for most people. This keeps the conversion simple and holds costs down.

* * *

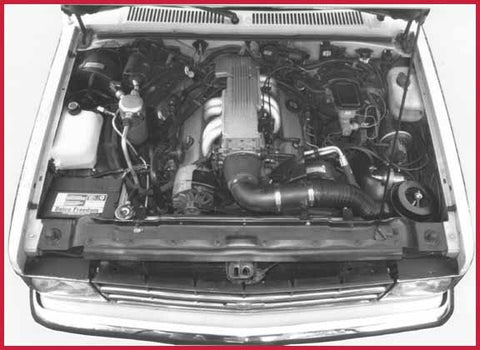

Under the hood, this 1988 TBI 305 V8 looks nearly stock in the S-Truck. This is because a lot of the parts are stock. We prefer stock parts because they are readily available and are of good, consistent quality.

With 235/75-15 tires and 3.73 gears, this Blazer gets about 22 mpg on level freeway trips at 65 mph. Normal overall fuel mileage is about 15-19 mpg. 0-60 mph takes ten seconds at sea level. This truck now weighs about 3900 lbs and has every factory option. The V8 conversion added about 190 lbs to the vehicle—210 lbs on the front axle and the rear axle lost 20 lbs of weight because the front of the engine is ahead of the front axle. The weight gain was noticeable with the stock front shocks—the front end would continue to cycle up and down after bumps. Installing stiffer front shocks returned the ride to nearly stock. Adjusting the torsion bars brought the front end up to the stock ride height.

Most people who drive the V8 S-10 Blazer do not realize it is a modified vehicle because the conversion works so well. No special knowledge is required to drive the vehicle. You just turn the key to make it start, and put it in gear to go. Just like a normal truck. The only noticeable difference from stock is the sound of the engine-driven cooling fan—it is noiser than stock, but it is not obtrusive, at legal freeway speeds, when the transmission is in overdrive.

At the time of this writing, the V8 swap has been driven over 55,000 trouble-free miles.

* * *

This 1984 S-15 2WD pick-up has a 1989 305 Tuned Port Injected (TPI) V8 engine from a Camaro/Firebird. The transmission is a New-Venture five-speed from a 1989–1995 full-size 1/2 ton truck. This truck is smog legal in California. The interior appears stock.

With the .73:1 fifth gear and 3.08 rear axle ratio, the engine turns 1700 rpm at 60 mph. Fuel mileage approaches 24 mpg at 65 mph on level roads. Normal trip mileage is about 22 mpg. Driven conservatively, overall fuel mileage is usually 17-21 mpg. It runs the 1/4 mile in 16.0 seconds at 89 mph.

As shown, this truck weighs over 3500 lbs and gained about 270 lbs from the conversion: 155 lbs on the front axle and 115 lbs on the rear axle. The V8 added about 190 lbs, the five-speed weighs 35 lbs more than the original Borg-Warner 5-speed, and the dual exhaust weighs 35 lbs more than the original exhaust; the battery was relocated to the rear (underneath the bed, in front of the right rear tire) to improve weight distribution? this transfers about 35 lbs off the front wheels and onto the rear wheels. A gear-reduction starter and an Edelbrock long style reverse-rotation aluminum water pump reduce engine weight (and front-end weight) by about 15 lbs.

We have seen magazine articles which state the V8 conversion only adds about 100 lbs to the vehicle compared to the 2.8 V6. You should realize that these claims are not true. Most people do not realize how much weight the conversion adds because with the correct heavy duty shocks, it is barely noticeable in normal driving. We tried several brands of front shock absorbers for the V8 S-10—we now prefer the Bilstein brand shock absorbers on the 2WD models. The front shocks on the 1996–1998 2wd trucks with the sport suspension option (ZQ8) are slightly stiffer than the Bilstein, but they also work well with the V8, and some people may prefer the ZQ8 shocks. Most of the 1996–1998 2WD Blazers come with Bilstein shocks.

* * *

After the V8 was installed, the front of the truck (which is equipped with the 1500 lb payload option) dropped less than an inch, the rear dropped about the same. The ride is slightly softer than stock, but most people do not notice much difference. The handling is not adversely affected. The most common comment made by people who drive the truck is not how powerful it feels, but how smooth and quiet it is. When the V8 conversion is done properly, the vehicle will feel stock, until you step hard on the gas pedal.

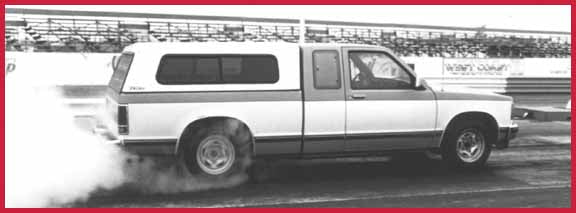

BURN-OFF TEST

Here, the vehicle is going through the Burn-Off Test™1 at the local dragstrip. It basically consists of revving up the engine, dumping the clutch and flooring the gas pedal (an MSD Soft Touch® rev limiter makes this test much safer by keeping the engine speed within safe limits). As you can see, the stock 7-1/2" rear-end (fitted with an Auburn limited slip differential) is up to the task. 1988 and newer 4.3 S-Trucks are equipped with even stronger 7-5/8" rear-ends and stronger axles. All 1993 S-Trucks have the 7-5/8" rear-ends. 1996-1998 trucks with the high-output V6 (L35) and 5-speed transmission come with an 8-1/2" rear-end which is very strong.

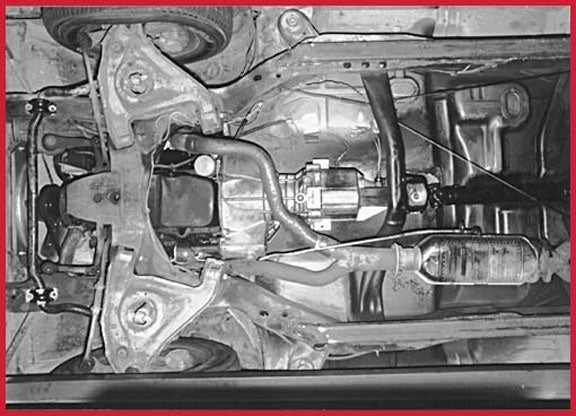

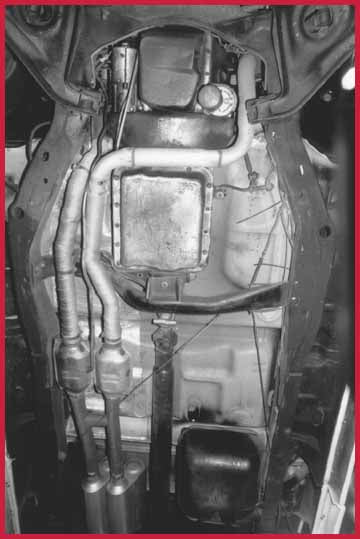

Underside of a 2-WD truck with a 305 V-8 and a 5-Speed

We tried the Burn-Off Test™ with sticky tires and a 500 lb load in the bed and sure enough, the stock 7-1/2" ring gear broke. We have broken a few differentials in other types of vehicles, so we have a good idea of what it takes to make them break. One of our ace testers has a bad habit of saying, "I never know how strong it was - until after I break it."

We tried the Burn-Off Test™ with sticky tires and a 500 lb load in the bed and sure enough, the stock 7-1/2" ring gear broke. We have broken a few differentials in other types of vehicles, so we have a good idea of what it takes to make them break. One of our ace testers has a bad habit of saying, "I never know how strong it was - until after I break it."

The stock 7-1/2" S-Truck rear-end is sufficient for most V8 conversions, but if you are running a "built" V8, or have tall or sticky tires, you will need the 7-5/8" rear end, or the 8-1/2" rear-end. Incidently, the 1982-1992 V8 Camaro use the same basic ring and pinion gears as the S-Truck, as do 1978—1987 V8 El Caminos and Monte Carlos. In fact, the V8 El Caminos and Monte Carlos only came equipped with the 7-1/2" ring gears and the smaller axles.

This is JTR's truck. It's a real truck (Not a Chevy, but a GMC!). At the time of this writing, this truck has over 200,000 miles, and the V8 swap has been driven over 75,000 enjoyable miles. One of the reasons this truck is so enjoyable is that the suspension has been modified with Bell Tech 2" drop spindles, de-arched rear springs with air shocks from a 1993 Typhoon (the softest riding air shock for the S-Truck), a 1-1/8" front anti-sway bar from an S-10 Blazer, and a quick ratio steering box (GM part #26040591) which has 2-3/4 turns lock-to-lock (from 1996—1998 S-10 trucks with the ZQ8 sport suspension). The steering box greatly improves the feel of the truck with good feed-back and quick, direct steering. The steering box is a bolt-on for 2wd trucks, but will not work on 4x4 trucks because the steering travel is different for the 4x4 models.

* * *

This wild looking 1987 S-15 Jimmy is owned by the renowned pinstriper, Herb Martinez. He told us he wanted a simple and reliable towing package to haul his 3,500 lb. trailer, we recommended the 305 TBI engine, and 700-R4 automatic overdrive transmission. Since Herb had a real truck (a GMC, not a Chevy), we decided to help him.

Herb initially wanted a TPI engine until we explained to him why we prefer the TBI engine for his application: Lower cost when compared to the TPI engine. We demonstrated the towing ability of the 305 TBI engine by hooking his trailer to our 4X4 S-10 Blazer. He also drove our TPI-five speed S-Truck for comparison purposes. After driving both vehicles, he agreed that the TBI engine would suit his wallet better than a TPI engine.

Herb chose a low-mileage 305 TBI engine from a truck, primarily to eliminate the AIR pump, and make the engine compartment look less cluttered while still being smog legal (actually, the real reason was that he got a great deal on the engine). Eliminating the AIR pump from the engine does little from a performance standpoint, and we normally prefer a Camaro engine, which has an AIR pump, because of its lower cost and better availability at the local wrecking yards.

Like most people, Herb was concerned about the stock 7-1/2" rear-end being able to withstand the power of the V8. Using the "power braking" technique (one foot on the brake and one on the gas pedal), we show the truck smoking the 265/50-15 Goodyear Gatorbacks. Herb showed us how he pinstripes cars and trucks. We at JTR taught Herb how to pinstripe asphalt.

After spending a week gathering parts for the conversion, we pulled the stock 2.8 V6 out of the Jimmy on a Saturday afternoon. The following Saturday, Herb was pulling a 3,500 lb trailer behind his newly V8ed truck on a 300 mile trip.

Later, the engine compartment was dressed up with components from Moon Equipment (coolant recovery tank and vacuum reservoir), Spectre (steel braided hose coverings and anodized aluminum fittings), and B&M (adjustable thermostat housing). The Stainless steel fan shroud and the aluminum covers for the battery and windshield washer bottle were custom fabricated (and very expensive). An onboard air-compressor from a Cadillac was also installed to fill the rear air shocks when the truck is loaded with cargo or towing a heavy trailer.

* * *

The engine in this vehicle is positioned 1" farther back than a "stock" position. This allows more room for the engine-driven cooling fan that is required for towing.

The vehicle now weighs about 3560 lbs. It gained 170 lbs from the conversion—190 lbs on the front wheels, and 20 lbs off the rear wheels. A gear reduction starter, and the lack of the AIR pump reduced the weight of the V8 conversion by 20 lbs, when compared to the 4X4 S-10 Blazer shown previously.

With the original fuel-injected 2.8 V6, 700-R4 transmission, and 3.73 gears, the truck averaged about 23 mpg on freeway trips, With the V8 and the 3.73 gears, the truck only averaged about 18 mpg on trips. Changing to 3.08 gears brought the freeway fuel mileage up to 22 mpg.

The stock 2.8 V6 would pull a 3,500 lb trailer up a nearby mountain pass at a leisurely 40 mph. With the 305 TBI V8, the truck pulls the same trailer up the same hill at 70 mph. With three people in the truck, 0-60 takes 9.6 seconds and it does the 1/4 mile in 17.4 seconds at about 79 mph (using a Vericom 2000 Performance Computer for measurements).

The engine swap was done when the truck had 152,000 miles. Herbie's truck has over 320,000 miles. It's had three breakdowns: the first time, the ignition coil died. Later, it was determined that the coil was damaged by a bad spark plug wire arcing into the coil (Coils rarely fail without a reason). The second time, the original in-tank fuel pump failed at 280,000 miles (but it gave a warning by making excessive noise for about a week before it quit). The third time it broke down (at about 281,000 miles), was when the ring and pinion in the rear end broke. It now has a 7-5/8" rear end from a 4.3 S-Truck.

While not considered breakdowns, the alternator was replaced at 250,000 miles and the water pump began leaking at 295,000.

* * *

This is the engine compartment of a Federal (non-California) 1984 2WD longbed S-Truck which originally had a 2.8 V6 and 5-speed transmission. The engine is a 1984 305 V8 from a light duty truck, and the original 5-speed was originally used. After the original 5-speed failed with nearly catastrophic results, it was replaced with a transmission designed for a V8. The engine is in the "forward position" and the driveshaft is unmodified.

Because this is a Federal (non-California) truck, it does not require a computer or oxygen sensor to be smog legal. It does have an AIR pump, EGR valve, PCV valve, EFE valve, thermostatic air, and fuel filler restrictor (unleaded fuel only). This is typical of what will be required in the non-California states that will soon be adopting California-type smog inspection laws.

A non-computer controlled V8 can be installed in the 1986 and older federal S-Trucks and still be smog legal in California because 1986 and older federal light-duty GM Trucks with V-8's did not use computer controls. If you do not want to install a fuel-injected V8 into your non-California truck, and your state has smog laws adopted from the California BAR 90 laws (Bureau of Automotive Repair, 1990), this conversion is a good example of what needs to be done to remain "smog legal".

This truck is not equipped with air conditioning, which makes the engine compartment look less cluttered than the other conversions shown. The radiator is in the "forward" position (which is explained in chapter 10). The weight gain from this V8 conversion is about 190 lbs: 210 lbs on the front wheels, and 20 lbs off the rear wheels.

* * *

1984 S-10 2WD TRUCK WITH 1989 305 TPI/700-R4

This is a 1984 S-10 2WD short-bed. It has a 1989 305 TPI and 700-R4 from a Camaro. This truck weighs about 3000 lbs and is very quick. Two twelve-inch electric cooling fans are mounted behind the radiator on custom brackets. The 85-89 Corvette radiator is actually mounted where the air-conditioning condenser would be on an air-conditioned S-10 Truck. Because of the lack of air-conditioning, and the attention to detail, the engine compartment looks very sanitary. Many people think this is a factory installation.

The owner purchased the V8 engine and transmission, and got all the parts required for the conversion before he removed the original V6/automatic powertrain. It took less than a week from the time he removed the V6 until the time he was driving it with the V8, but the owner is very talented, and very experienced with automotive work. Also, this is a a fairly simple swap because it is a two-wheel-drive truck, and it is not air-conditioned. The engine is in the "forward" position, and the driveshaft is stock. At the time of this photograph, this truck had been driven over 60,000 miles.

* * *

We put a 1989 350 TPI into this 1985 4X4 S10 Blazer for a magazine article. As you can see, it's a tight fit. Due to space limitations, cooling is the biggest problem with the V8 S-10 conversions, especially on the 4X4 models. A lot of information in the cooling system chapter came from this conversion. This conversion took two very long weeks to complete.

We installed an NOS® nitrous oxide system, and ran it in the quarter mile. In 4-wheel-drive high-range, it ran 13.7 at 95 mph with 235/75-15 Goodyear All Terrain tires. Without the nitrous, it runs 15.2 at 88 mph. Remember, this is a 4-wheel-drive with skid plates and heavy off-road tires. It weighs 3900 lbs. What amazed most people is that the stock axles and transfer case handled the power without breaking. To further demonstrate how strong these parts are, we chained the truck to an immovable object (otherwise known as a one-ton crew cab dualie) and smoked all four tires. The tires actually dug holes in the asphalt.

With the original carbureted 2.8 V6, 700-R transmission and 4.11 gears, the truck averaged 18 mpg, and took forever to do 0-60 mph. The truck now averages about 15 mpg, but it is a lot more powerful and the drivability is much better than with the original engine. Installing 3.42 gears would probably bring the average gas mileage up to 18 mpg.

In case you are wondering about the custom wheels, they are off a 1990 Jaguar XJ-6 and they bolted on with no adapters, but they did require special lug nuts.

At the time of this writing, the truck has over 200,000 miles, and has been driven over 60,000 miles with the V8. The original rear-end required replacement at about 170,000 and the radiator has been replaced twice: once when the fan contacted the lower radiator support (see page 10-1), and another time when the water pump bearing wore out and the fan contacted the radiator. Read the chapter on the cooling system very carefully for important information on fan/radiator clearance.

And then there is the time the engine seized when the hose going to the remote oil filter failed. Be sure to use the correct hoses for the application, and check them regularly to be sure they don't get brittle! Or use the offset oil filter adapter (page 3-10), and don't worry about the hoses.

* * *

Project ZZ3—OUR QUICKEST TRUCK

Note: The engine shown in this truck is no longer available from GM. It has been replaced by a slightly more powerful engine called a ZZ4. It is no longer possible to do this exact swap because some of the parts are no longer available. We continue to show this truck because it shows what can be accomplished while still being legal. We believe that similar performance can be achieved with smog-legal aftermarket performance parts. Today, it is possible to purchase smog legal high-performance cylinder heads, camshafts, intake manifolds. A 350 Truck TBI engine with the Edelbrock performance package (aluminum cylinder heads, camshaft -- with matching computer chip -- and intake manifold) is probably the most comparable smog-legal package.

The engine package installed in this 1987 truck is the "5.7 liter High Output Camaro Conversion" (GM part #10185077) which is rated at 308 horsepower in smog legal trim for the 1982-1987 Camaros and Firebirds. It was developed by GM Motorsports Engineer Mark McPhail for the 1982–1987 Camaro/Firebird. Because California smog laws allow engine swaps as long as all of the emissions controls are installed and operating, this engine package (which requires the 700-R4 transmission) is also legal in 1982–1987 S-Trucks (more information on smog laws is in chapter 14). By the way, this is JTR's truck. It's a real truck (a GMC, not a Chevy!).

The engine in this engine package is the ZZ3 345 horsepower High Output "crate" motor. The ZZ3 has aluminum heads, aluminum intake manifold, high lift roller cam, forged steel crank, 4-bolt mains, "pink rods", and hypereutectic pistons with a compression ratio of nearly 10:1. The package includes a cold air induction dual-snorkel air-cleaner from a 1983–1985 Camaro with the L69 engine, dual catalytic converters from a 1990–1992 Camaro with the 350 TPI engine, a Holley fuel pressure regulator, specially calibrated carburetor secondary rods, and special transmission parts that increase the shift firmness and improve the durability of the 700-R4 transmission when used with the ZZ3 engine. The parts list and instructions is too long to put in this manual and is available from GM as part #24502463. The information on the transmission modifications is very important because it makes the package work so well with proper shift points and firmness.

The "smog equipment" is not totally responsible for reducing the horsepower rating from the ZZ3's original 345 down to 308 (37 horsepower). According to GM engineers, the Camaro's low hood line requires a short air cleaner which is responsible for about 8 horsepower. The Camaro's H.O. exhaust manifolds are responsible for another 20 horsepower, compared to dyno headers. The dual catalytic converters reduce output less than 10 horsepower, and the smog pump consumes less than 1 horsepower. The S-Truck has room for a taller air cleaner (from a Monte Carlo SS), but the exhaust manifolds required for the S-Truck chassis may drop a few horsepower compared to the Camaro H.O. exhaust manifolds, so overall, the Camaro H.O. conversion package in the S-Truck is very comparable to the Camaro's 308 emissions legal horsepower.

To make the finished installation look simple and uncluttered, we intentionally chose a truck without air-conditioning and we set the engine back 1-1/4". This required reshaping the transmission tunnel with a hammer, and it required massaging the firewall for the automatic transmission shifter on the steering column. Additionally, we installed a set of headers for evaluation purposes (We prefer the cast-iron exhaust manifolds which are now on the truck!). Even with the engine set-back 1-1/4", the big HEI distributor required no firewall modifications. This conversion took a very long time to complete. Making it look easy, was hard.

We always install an MSD™ Soft Touch™ Rev Control to our stick-shift vehicles but it was also installed onto the ZZ3 truck. With previous bad experiences caused by "over-enthusiastic" drivers damaging engines, we didn't want to risk hurting the H.O. engine. The rev limiter costs less than $100, and we believe it should be installed on every high-performance engine. It's amazing to us how some people, after driving our vehicles, would comment on the "high speed misfire." What they were really telling us is that the rev-limiter saved another engine from damage.

Underneath the ZZ3 truck is a 2-1/4" dual exhaust system. Dual catalytic converters were a part of the 5.7 liter H.O. Camaro Conversion package, and were legal in this application (The headpipes and converters from the Camaro package will not fit the S-Truck V8 conversion. This truck has custom made headpipes, and universal replacement high-flow catalytic converters). Flowmaster two-chamber mufflers are used, and an exhaust crossover pipe behind the catalytic converters smooths the sound out the tailpipes.

To reduce the heat going into the passenger compartment, the headpipes are wrapped with Thermo-Tec® exhaust insulation wrap, and Thermo-Tec® aluminized heat barrier is attached to the underside of the cab, above the exhaust.

Originally it was decided to keep the truck as light as possible for best performance. The truck had few options, and the aluminum heads and intake manifold used on the ZZ3 engine saved about 60 lbs compared to a "normal" V8 engine. An Edelbrock long-style aluminum water pump (the only long-style auminum water pump on the market that will work with the stock Camaro accessories) dropped 6 lbs off the front end, a 1993 Camaro LT1 gear reduction starter saved another 9 lbs. To improve weight distribution, the battery was relocated behind the right rear wheel. Aluminum brake drums off an IROC Camaro saved another 9 lbs.

Without power steering and power brakes, the truck weighed less than 3000 lbs with the 20 gallon tank full of fuel, so with over 300 horsepower, it should have been a fun and wildly fast truck.

Wildly fast?‹Yes! Fun?‹Not really.

The power overwhelmed the stock 4-cylinder shocks, front springs, and lack of anti-sway bars. The manual steering was too heavy and too slow. The non-power assist brakes took too much effort. And perhaps most frustrating of all was that without a limited-slip differential, it would spin the right rear tire all too easily, severely limiting acceleration.

In other words, there was still more work to do!

Suspension parts from a 1996-2000 ZQ8 equipped 2WD S-10 truck were installed on the 1987 truck. The ZQ8 parts list includes stiffer shocks, 1.3" diameter front swaybar, rear sway bar, front and rear springs, a quick ratio steering box. The parts are listed in the Chevrolet Performance Parts Catalog, which is available from your Chevrolet dealer.

Bell Tech Drop spindles and lowering blocks also help lower the truck. Power-steering and power-brakes were added, along with the rear-wheel anti-lock brake system from a 1989 S-Truck. The power steering and power brakes made the truck easier to drive, and the suspension parts made the truck handle better, but the ZQ8 parts made the ride stiffer. Some people like the stiffer ride, some people don't. If you want sway bars that are stiffer than the ZQ8 parts, Hotchkis Performance makes front and rear sway bars that are similar to the ZQ8 parts, but thicker and stiffer.

To improve drivetrain strength and traction, a 4.3 S-Truck rear axle assembly (7-5/8" ring gear compared to the stock 7-1/2" ring gear) and an Auburn limited-slip differential were installed. The limited-slip differential dramatically improved the truck's ability to accelerate out of corners without spinning the inside rear tire. With street tires, the Auburn limited-slip differential dropped the 0-60 mph time to 5.7 seconds, compared to 6.3 seconds without it.

Even though the above suspension and brake modifications added weight, the truck became fun! It corners, it accelerates, and it stops with the best of them. The engine makes the truck so fun that the MSD™ Rev Limiter is constantly being put to use. At a steady 65 mph, the lightweight truck gets 22 mpg with its 3.42 gears. But because of the happy feet we get driving it, the fuel consumption has been averaging about 14 mpg.

Our best 1/4 mile run on street tires was a 13.9 at 105 mph on a 100 degree F day with the headers, but without the limited-slip differential. With slicks, the limited-slip differential and cooler weather (but with the cast-iron exhaust manifolds, power-steering, power brakes, and swaybar) a 260 lb magazine editor ran a 13.3 second quarter mile at over 102 mph. Four years later, with a quieter (more restrictive) exhaust, an engine-driven fan, and more weight (heavier tires and wheels, hard tonneau cover, body mods, sound-deadening, rear bumper, etc), the truck only ran 98 mph in the quarter mile. Because the truck does not have a tach, all runs were done with the shifter in drive, shifting at about 5300 rpm. The GM engineer who developed the ZZ3 package says it would run faster if shifted at 5800 rpm.

* * *

1984 S-10 BLAZER WITH 1985 305 TPI/700-R4

The owner of this truck told us that he would do the swap in about a week. Even though this person is a factory trained technician for a Chevrolet dealership, we had our doubts. He wanted to do too many things that would take time. The truck was originally a stickshift, and he had to convert it over to an automatic. He wanted to run electric cooling fans and air conditioning. He wanted to run dual exhaust. He wanted the engine compartment to look nearly stock. And he wanted a nearly naked lady to pose with the truck. He did all of the above, but it took much longer than a week. We can't show you the nearly naked woman. Sorry.

The engine and transmission for this project actually came about from watching the television show, America's Most Wanted. It seems a regular customer dropped off a 1985 IROC Z Camaro at the dealership for repairs. While watching America's Most Wanted, the technician recognized the owner of the Camaro, who was wanted for suspicion of murder. To make a long story short, America's Most Wanted got their man, and the owner of the above truck got his engine and transmission. As the owner put it, "I got a killer deal." We are not making this up.

The engine is almost completely as it comes out of the 1985 Camaro, except for the exhaust manifolds, the routing of the wiring harness, the Corvette valve covers, and the routing of the A.I.R. hoses. The air conditioner accumulator is from a 4.3 V6 S-Truck to improve hose routing.

The engine is set back about 1-1/4" to provide room for the 4.3 V6 radiator and the Flex-a-lite model 210 electric cooling fan (see page 10-24) which is mounted behind the radiator. The radiator is positioned about 1/2" more forward than the stock position, and the radiator core support had to hammered slightly to provide room for the radiator cap. As you can see, it is a bit crowded, but everything fits, and this is a worst case example for room between the engine accessories and the fan/radiator combination. This cooling system works o.k., but it has not been tested in weather over 100 degree F at the time of this writing. We prefer an engine-driven fan for this swap.

It was the details that took so much time to complete this swap. It took hours to make nice looking brackets to mount the radiator, cooling fan, and air cleaner ducting.

This V8 swap looks so stock that it is very hard for the average person to understand the many details that required skill, money and time.

* * *

BABY THUNDER, 1992 S-10 4X4 TRUCK WITH 1992 CORVETTE LT1 ENGINE

This was built by GM wizard, Scott Leon, at the General Motors Arizona proving grounds. The detail and workmanship on this conversion are first rate and nearly all of the conversion was done with GM parts. The elbow from the throttle-body to the air-cleaner is custom made, and it is a work of art. It is actually made from a few accumulators for the air-conditioner. We can¬t begin to guess how many hours went into making that piece. Stealth Conversions now has a 90° rubber elbow that performs the same functions (see our ducting parts here.)

Even when using an LT1 engine, this swap is similar to what we recommend. However, the Corvette LT1 engine accessories (air conditioning, power-steering pump, alternator) and brackets must be used for this swap. The accessories used on the Camaro LT1 will not fit the S-Truck 4X4 chassis, but they will fit a 2wd chassis (see chapter 7).

This engine swap is slightly different than what we recommend in that the transmission and transfer case remain in their stock location. The driveshafts remain stock and the evaporator cover remains stock. No modifications were required on the firewall or transmisson tunnel. For cooling, two 150 watt (12 amps) GM fans were mounted in front of the radiator and the 1992 grille was modified for fan clearance. These appear adequate for moderate weather conditions. Remember, the only reason we recommend moving the engine rearward is for improved cooling. Moving the engine rearward requires modifications to the driveshafts, evaporator cover, firewall, transmission tunnel, and shift linkage, but we feel it is necessary with an air-conditioned V8.

Due to the air cleaner position, the 4.3 V6 radiator was offset to the driver's side a couple of inches, and a small battery, group size 70 replaced the larger, group size 78 battery.

The engine compartment of "Baby Thunder" is packed full of options and accessories. The fourwheel-anti-lock-brake module takes up a good amount of space. The cruise control, remote oil filter, and the remote power steering reservoir take up even more space. The hose fittings on the air-conditioning compressor were tig welded to route the hoses downward through a small amount of available space. This swap was no small feat.

Due to the "forward" positioning of the engine, the stock 4.3 V6 radiator tank did not allow room for the LT1¬s upper radiator hose. The side tank on the 4.3 S-10 radiator was replaced with the side tank from a 1990-1991 Pontiac Grand Am, GM part #52452789, and a couple of radiator hoses were spliced together to make the upper hose.

If the engine was set back 1 inch, and the radiator mounted forward 1/2 inch as we recommend, a stock 4.3 V6 radiator could probably be used, and a pair of thin 12" electric cooling fans could be installed behind the radiator, as was done on the truck shown on page 1-16. In addition, if the engine was offset towards the passenger's side, an offset oil filter adapter (see page 3-10) could be used instead of the remote oil filter, freeing up some more space. Still, another option is to use the cooling system that was installed on the LT1 powered Blazer shown on page 1-24 and 1-25.

A throttle-body from a 1993 Camaro LT1 engine was installed onto the 1992 Corvette engine. This was done because the throttle-body used on the Corvette has no provisions for the transmission¬s throttle valve cable and cruise control. Those cables are attached to the traction control module that comes standard on all LT1 Corvettes.

Underneath "Baby Thunder", the truck is essentially a Syclone with an LT1 engine. The Syclone uses a full time 4-wheel-drive transfer case from the all-wheel-drive Astro Van or Oldsmobile Bravada. The Syclone, Typhoon and Oldsmobile Bravada also use a different torsion bar crossmember which hangs a bit lower than the standard 4X4 S-Truck torsion bar crossmember, and allows room for a 3 inch exhaust pipe. The transmission crossmember is also unique to the Syclone, Typhoon, and Oldsmobile Bravada. The front driveshaft is also different than a standard 4X4 S-10 in that it uses a constant velocity joint instead of a U-joint. The Syclone also uses a console mounted Corvette floor shifter with cable actuation, which makes the shifter hook-up easier.

2-1/4" headpipes join into a 3" catalytic converter from a 1994 full-size truck with the 454 V8. We recommend using 2" head pipes on the 4X4 V8 swap because of the tight clearance, but GM's Scott Leon is far more skilled and patient than your average muffler shop.

Notice the license plate, which says "MANUFACTURER" on the bottom. If it didn¬t say that, we would have tried to take credit for building the truck.

From the rear, the truck looks nearly stock, even with the 1993 Corvette tires and wheels. The tires are Goodyear GSC, 255/45ZR17 front, 285/40ZR17 rear. The rims are 8.5x17 front, 9.5x17 rear, and they bolted on with no adapters. The 4-wheel-drive S-10 trucks use different wheel offset than the 2-wheel-drive trucks, so these wheels will not bolt onto a 2-wheel-drive truck unless adapters are used.

The rear suspension was lowered slightly by removing a leaf spring. This also softened the ride slightly. The rear brake drums were replaced with aluminum drums from an IROC Camaro. These changes saved about 30 lbs.

The rear bumper is from an S-10 Blazer and the handle for the spare tire carrier was modified slightly for access to the spare tire. These details are what separates a complete factory type conversion from the novice. This also shows how making a simple change like replacing the bumper can be more work than expected.

The truck weighs 3456 lbs, with a weight distribution of 64/36, front/rear. A GMC Syclone, which is essentially the same vehicle, but with a turbocharged and intercooled 4.3 V6 engine rated at 280 horsepower has a published curb weight of 3526 lbs. The Syclone comes with a tonneau cover and special ground effects body parts which add a few pounds, but it is interesting to note that the Corvette LT1 engine with aluminum heads actually weighs about the same as a 4.3 V6 with a turbocharger and intercooler. The turbocharger and intercooler weigh at least 50 lbs.

This truck is a blast to drive. It is smooth, quiet, and very fast. It runs the 1/4 mile in 13.9 seconds at 98 mph. The all-wheel-drive transfer case makes it possible to do full throttle starts without wheel spin—even in the rain! The LT1 engine idles smoothly and pulls solidly right up to the redline (6000 rpm). Because of the traction, the full throttle 1-2 shift is quite harsh. For example, our ZZ3 powered truck spins the tires on full-throttle 1-2 upshifts, and with Baby Thunder, the four tires grab so hard that it feels like the rear suspension bottoms out during full throttle 1-2 shifts as your head bangs against the headrest during the shift. It's actually kind of fun!

* * *

ZZ3 UPDATE

We left the ZZ3 powered truck with a magazine editor for over a year. The truck racked up about 10,000 miles, an unpaid parking ticket, and a Hit-and-Run accident. To make a long story short, the editor claimed he had nothing to do with the accident, but he paid the owner of the other car cash, within 24 hours of getting informed of being a suspect. Something about the "LEGAL V8" license plate was easy for witnesses to remember. Even more coincidental was the fact that the editor looked remarkably similar to whoever was driving the truck when it hit the other vehicle.

After we got the truck back from magazine-land, we decided it was time to add air-conditioning. As you can see, we installed an engine-driven cooling fan (hidden by the fan shroud). We prefer engine-driven fans over electric fans. With the engine set-back 1-1/4", a 1" thick fan spacer is used, and there is 1-1/8" between the fan and the radiator. A 5/8" fan spacer would work with the accessories shown, so the engine/transmission would only need to be set-back about 7/8" for adequate fan clearance.

The air conditioning compressor and bracketry are from a 1987 V8 Camaro. The accumulator is from a 4.3 V6 S-Truck. The air-conditioning hoses are from a 1982–1984 V6 Camaro and bolt up to the truck with mild tweaking on the end that attaches to the compressor.

The fan is 18" in diameter, and the fan belt to the a.c. compressor must be long enough to clear the tip of the blade, but short enough to keep the compressor away from the upper radiator hose. Also, the radiator must be offset towards the driver's side so that the a.c. compressor doesn't contact the upper radiator hose. In other words, it all fits, but it is tight.

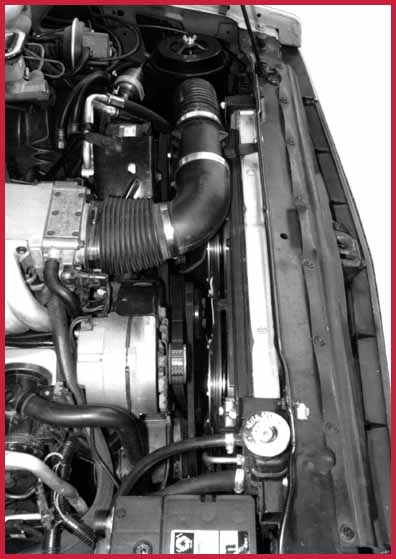

ANOTHER UPDATE

This is the truck shown on page 1-9, but with a 350 TPI engine and a Vortech supercharger. As simple and clean as this installation looks, it must be noted that it wasn't completely simple. The biggest obstacle to this installation was that the alternator could not be mounted as per the kit because the steering box was in the way (remember, the kit is for a Camaro!). Custom brackets were made so that the alternator could be mounted where the air-conditioning compressor normally goes, but this truck is not equipped with air-conditioning.

Another obstacle with this installation is the clearance between the supercharger, the upper radiator hose, and the radiator. But remember, the engine is installed in the "forward" position (which doesn¬t require driveshaft modifications). It all fits, but it is a bit too tight for our tastes. Setting the engine back even 1/2" would noticeably improve working room.

The supercharger and mounting brackets weigh about 50 lbs.

We have no performance numbers for this truck, as it was sold shortly after this photograph was taken.

* * *

1995 CAMARO LT1/4L60-E INTO 1988 2WD S-10 BLAZER

At this time, we don't recommend the LT1 swap for people who want to do a simple and inexpensive swap. The LT1 swap is expensive, complex, tedious, and expensive. Did we mention it can get expensive? If your friends tell you how neat it will be to install an LT1, remember this, most LT1 swaps into the S-10 don¹t get completed.

The owner of this Blazer went out and purchased an LT1 out of a wrecked 1995 Camaro, thinking it was like any other small-block V8. The LT1 engines are significantly different than the "conventional" small-blocks, and are more difficult to install into the S-10.

As this book was going to print, we had been following the Camaro LT1 swap into the Blazer. This swap is a lot of work, but the experience and knowledge gained from this swap carry over to "normal" small-block S-10 V8 swaps, and made it possible to improve the refinement and performance of the V8 swap.

One of the goals of this swap was to use the Camaro LT1 exhaust manifolds so as not to restrict the performance of the engine. Also, the air-cleaner ducting had to be efficient, again, so as not to restrict the power of the engine. The engine should be able to put out its full rated 285 "net" horsepower. In magazine numbers, it would be more like 375 "gross" horsepower.

Also, the cooling system had to function so that the engine would not overheat in hot weather while the air conditioning was putting cool air into the passenger compartment.

As you can see from the above photo, the LT1 swap looks quite good. What the photo doesn't show, is how much work, skill and money was involved in completing this swap.

The radiator was moved forward to where the a.c. condenser used to reside. An aftermarket a.c. condensor was installed in front of the radiator (see page 10-14). The air cleaner is from a 1993 S-10 with the 4.3 CPI V6. The rubber elbow attached to the throttle body is from a 1LE Camaro (the "1LE" elbow doesn't have the noise cancellation tube), and it was trimmed about 3/4" to improve clearance from the Ford Taurus cooling fan. Two 3-1/2" x 45 ° rubber elbows (from Stealth Conversions) join the air cleaner assembly to the LT1 MAF sensor.

The Camaro LT1 exhaust manifolds required notching the frame on the passenger¹s side, and installing a modified Ford F-150 steering shaft (see page 7-28). In addition, the engine is offset to the passenger's side by 1" to improve clearance between the exhaust manifold and the steering shaft.

The owner opted to mount the LT1 engine computer onto a 1995–1998 S-10 coolant recovery tank, because that is where the computer is mounted on 1995–1998 S-10's. Mounting the late model coolant recovery tank into the older truck required custom brackets, and modifications to the inner fender panel. In addition, the heater hose fittings on the heater core required shortening, and heater hoses required rerouting.

The point: If you want to install an LT1 into an S-10, you must understand the nature of the swap, and how difficult, expensive, and time-consuming it can be.

* * *

V8 ALTERNATIVE FOR 1996–2000 TRUCKS WITH THE 4.3 V6

This 1998 S-10 truck has a Vortech supercharger. The performance of the supercharged V6 is similar to that of a V8 powered S-10 truck. The supercharger system adds 50 lbs to the front of the truck.

Cost of the Vortech Supercharger for 1996–2000 S-10 Trucks with the 4.3 V6 is about $3200. This may seem like a lot of money, but it is less costly than a typical V8 swap on a 1996–2000 S-10 truck, and it takes a lot less time. It took the author about 16 hours to install the kit, which comes complete with an additional fuel pump, boost retard ignition system, and auxiliary fuel management system. The author could probably do the job a second time in 8 hours.

Vortech advertises the supercharger to increase horsepower from 175 (stock) to 243. Based on the performance improvements on this particular truck, the advertised claims are accurate, if not a bit conservative. The supercharger is an interesting way to improve performance, and there is potential to improve performance even more. The truck above weighs 4000 lbs with the driver. Fully warmed up, on a 50° F day, it runs 93 mph in the quarter mile and does 0-60 mph in 6.8 seconds with 3.08 gears and an automatic transmission. With 3.42 gears, it would be quicker. Using a formula (HP= weight of vehicle X (trap speed/225)(3.144 power), the horsepower is calculated to be 245 with the supercharger. Stock, the truck did 81 mph in the quarter mile‹using the above formula, the 175 horsepower rated engine is calculated at 160 (the automatic transmission probably eats up 15 horsepower). With exhaust modifications (headers and cat back system) the truck did 83 mph in the quarter mile (which calculates to 175 hp) without the supercharger.

The Vortech supercharger increases power reliably when installed per Vortech¬s instsructions. We do not, however, believe a supercharged truck should be driven under boost for long periods of time. In other words, it is great for passing and accelerating onto the freeway, and quarter-mile racing. However, if you plan on towing a heavy trailer behind your truck up a long hill, you should not keep your foot to the floor for more than a few seconds at a time because the heat build-up inside the engine could damage the stock pistons. At high altitudes (above 4000 feet), where the air is thin, it is probably ok to drive under high boost for longer periods of time.

The latest Vortech superchargers are nearly silent. The power increase from the supercharger is minimal at engine speeds below 2500 rpm. At 3000 rpm, the supercharger delivers about 3 lbs of boost and the power increase can be felt. At 5500 rpm, boost is 9 psi. By removing the snorkel on the air-cleaner assembly, and enlarging the intake opening on the air-cleaner assembly, boost improved to 12 psi at 5500 rpm. Improving the exhaust system also improved performance. To make a long story short, supercharged engines respond well to free-flowing exhaust systems and low-restriction cold-air intake sytems—a whole book could be written about superchargers and ways to improve the performance of supercharged engines.

It should be noted that the supercharged V6 is more sensitive to outside temperature than a non-supercharged engine, and when doing repeated 1/4 mile runs with no cool-down periods, the performance drops noticeably due to increased temperatures in the intake track and supercharger. Also, the supercharger requires premium fuel.

Reducing Wheel Hop

If you notice the rod hanging below the leafspring, it is a prototype torque-reaction-rod which reduces pinion angle changes caused by axle wind-up. Its function is similar to traction bars, but it does not noticeably affect the ride. It is designed to be completely streetable, and should be available from Stealth Conversions by the end of the year 2000. Estimated price for a pair of torque-reaction-rods is $250.

1985 S-10 Blazer 4x4 with a 350 TPI V-8 and a 700-R4

One last example: the 460 TPI V-8 we put into this 4WD Blazer along with a 700-R4 transmission helps it run the quarter mile in 15.7 seconds at 89 mph. We used the stock transfer case, driveshafts, and front and rear axles.

* * *

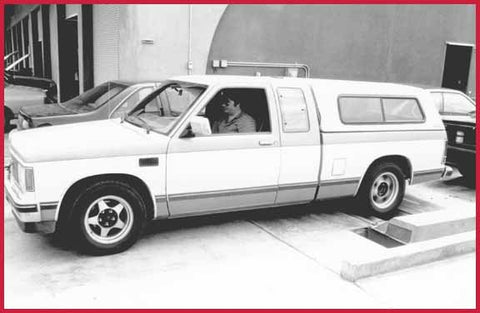

MEASUREMENTS

We are not sure how some people measure horsepower, performance, and fuel mileage, but we use a chassis dynamometer to measure rear wheel horsepower. To measure performance, we use a Vericom 2000 on-board Performance computer (accelerometer), or we go to the dragstrip. We measure gas mileage by dividing distance traveled by fuel consumed. And we use accurate scales to measure vehicle weight and weight distribution. We do a lot of measuring, not guessing.

The point to this is: The performance numbers, the weight figures, and the fuel mileage numbers given in this manual are accurate and repeatable.

Notice the bored appearance of the dyno operator in the driver''s seat. Gathering accurate information is tedious and time consuming.

The listed weights of the vehicles shown in this manual may seem high, but they are accurate (±25 lbs), and the high weights definitely account for the durability and comfort of the S-Trucks, especially when compared to many of the imported mini-trucks. The original 2.8 V6 engines were not underpowered, they just had too much weight to move.

* * *

TYPICAL CONVERSION COSTS

|

1.

|

Motor mounts |

$95

|

|

2.

|

Radiator: Corvette type heavy-duty |

$150

|

|

3.

|

Electric cooling fan with adjustable temperature switch |

$85

|

|

4.

|

Engine-driven cooling fan and fan spacer |

$55

|

|

5.

|

Radiator hoses and heater hoses |

$50

|

|

6.

|

Exhaust: complete, with new catalytic converter |

$450

|

|

7.

|

Fuel tank with electric fuel pump (from wrecking yard). Not needed on vehicles that came with fuel injection, or vehicles that will be using a carbureted engine. |

$100

|

|

8.

|

Fuel hoses and transmission cooler lines |

$20

|

|

9.

|

Throttle cable bracket (Edelbrock part #8036) |

$20

|

|

10.

|

Battery tray (1987 and older vehicles only) |

$15

|

|

11.

|

Oil, antifreeze, transmission fluid |

$30

|

|

12.

|

Front shocks |

$150

|

|

13.

|

Miscellaneous wiring and fuses |

$40

|

|

14.

|

Miscellaneous: hose clamps, nylon tie-wrap, vacuum hoses, tune-up parts, nuts and bolts, paint, filters, etc. |

$300

|

|

15.

|

S-10 Truck V8 conversion manual (BARGAIN!) |

$30

|

|

16.

|

Driveshaft modifications |

$80

|

|

17.

|

Air conditioning evacuation and charge |

$200

|

|

18.

|

Fan Shroud |

$100

|

| For a 4X4 conversion, add: | ||

|

19.

|

Custom oil pan |

$250

|

|

20.

|

Automatic transmission modifications |

$100

|

|

21.

|

Offset oil filter adapter (see page 3-10) |

$40

|

|

22.

|

Front driveshaft modification (see page 2-6) |

$35

|

|

23.

|

Additional electric cooling fan |

$85

|

| Typical engine cost: | ||

| 1991 305 TBI V8 engine and 700-R4 transmission from Camaro, complete with all accessories, hoses, wiring, computer, exhaust parts, charcoal canister, etc. |

$1500

|

|

| For a 1991 305 TPI engine, add $500 to $1000 to the cost of the above | ||

| For a 1991 350 TPI engine, add $500 to $1000 to the cost of the above | ||

These are actual prices a retail consumer should expect to pay (in Northern California) for the parts needed to perform a high quality,

California smog-legal conversion. In California, we are required to use computer-controlled engines that are no older than the truck.

TIME REQUIREMENTS

The time needed to do the conversion will vary substantially from person to person. An experienced mechanic with the proper

equipment should be able to perform the following tasks in the time shown.

|

1.

|

Remove S-Truck engine/transmission, clean and de-grease vehicle and engine compartment |

8 hours

|

|

2.

|

Modify engine compartment for V8 installation |

8 hours

|

|

3.

|

Engine preparation (engine dress) |

4 hours

|

|

4.

|

Engine installation (includes time to test fit engine until everything fits) |

8 hours

|

|

5.

|

Wiring/electrical for fuel injected engine when using Camaro harness and adapting it to the S-Truck harness. Time includes studying the shop manuals and is meant for the experienced only. |

40 hours

|

|

6.

|

Change fuel tank (fuel injected engines) |

4 hours

|

|

7.

|

Parts chasing |

30 hours

|

|

8.

|

Read and study the V8 conversion manual |

4 hours

|

|

9.

|

Muffler shop |

4 hours

|

|

10.

|

For a 4X4, add another 16 hours. |

|

Make no mistake about it, a high quality V8 conversion is going to cost a lot more than replacing the stock engine, and is going to take a lot more time.

For many people, it may be a better decision to buy a newer S-Truck with a 4.3 V6 than to convert the old S-Truck to a V8.

However, for those who are mechanically inclined and want more power than the factory offers, the V8 conversion may be the better deal. Also, the V8 runs noticeably smoother than the 4.3 V6. Beginning in 1993, a balance shaft was designed into the 4.3 V6‹the 4.3 V6 engines with the balance shaft are very smooth.

As for the resale value of a V8 S-Truck, we have no figures at this time, but modified vehicles are usually difficult to sell, and are usually sold at a financial loss.

On the positive side, doing the engine swap instead of buying a newer model means you save on monthly payments, you save on registration fees, and you save on new car tax and license fees.

AVOIDING THE WAITING GAME

A lot of the Chevrolet parts needed for the V8 conversion are not normally stocked by your local dealer, and may need to be ordered in advance. If you find yourself needing the parts in a hurry, your Chevrolet dealer can "V.I.P." the parts for an additional fee.